SERVICES

Design of Electrical Systems

Redpoint Engineering undertakes concept and detailed design of electrical, control and instrumentation systems for building, mining and industrial applications. Typical projects include upgrading or replacing of HV/LV systems, specific mechanical system upgrades and building service systems design.

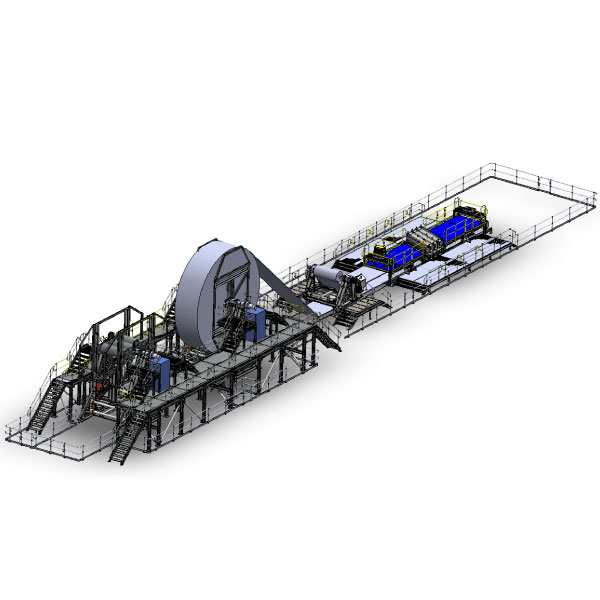

Belt Shed

The Belt shed project housed an Automatic Conveyor Belt Dispensing System. This system was designed to dispense the correct length of conveyor belt material from the spool delivered from the factory onto smaller spools.

The operator then splices the belt and prepares the end before the system prepares the spools for dispatch. The material on these smaller spools was then installed on our Client’s conveyor belts.

In this project, we were responsible for power distortion, instrumentation, control system, machine safety, and communication design, ensuring that the desired automatic features operated accordingly.

Business Case Development

Redpoint Engineering provides engineering support to enable our clients to obtain project funding.

Ship Loader Substation Upgrade

We were commissioned to review and provide an concept design and budget price to updgrade the three MCCs on our Client’s ship loader specially as the equipment was end of life and did not meet current safety requirements.

Redpoint Engineering conducted a feasibility study to suggest a viable design and project budget for replacing the ship loader switch room while interfacing with the existing field equipment.

Design Verification

Redpoint Engineering undertakes independent reviews of existing designs to verify equipment for compliance with Australian and Client Standards.

Vulcaniser Compliance

Vulcanisers are used to splice the conveyor belts. This is done by controlling the heating pads to maintain the temperature for the right duration. The Western Australian mining regulations have specific requirements for this equipment, so an independent consultant must review and verify this equipment.

We were not involved in the equipment design but were responsible for verifying that each model complies with AS/NZS 3000 and otherrelevant standards required by the mining regulations.

Drafting & Tracing

Redpoint Engineering undertakes 3D and 2D drafting of electrical systems. Typical 2D and 3D deliverables include tracing schematic diagrams, panel layouts, and 3D modelling of plant infrastructure.

Site Audit

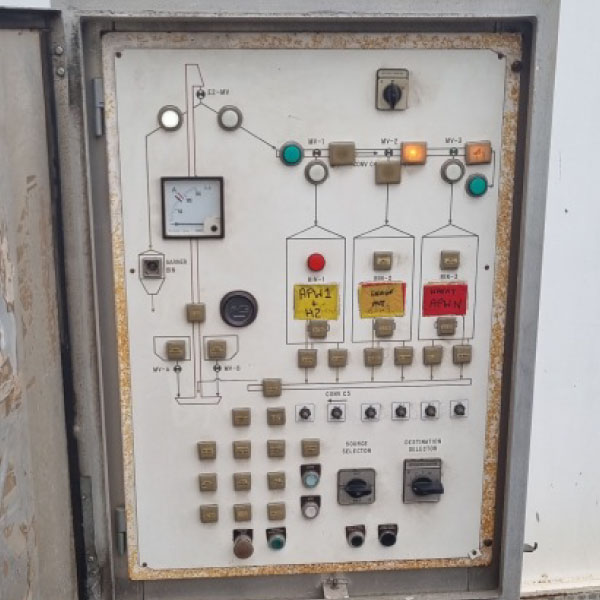

We undertook a complete site review of a site’s electrical, instrumentation, and control system drawings to verify and amend them to as-built status for use by the operational staff.

At this regional site, our drafting team spent five days on-site investigating the status of all the drawings before returning to the office to supersede, amend, or cancel the required drawings. The drafting team returned to the site to verify concerns before making the final amendments and issuing the drawings.

Electrical System Review

Redpoint Engineering provides engineering assistance in resolving electrical problems. In these projects, we review the system faults to eliminate potential causes and identify the most likely issues. As part ofthis project type, we provide a findings report identifying the steps undertaken duringthe investigation and our conclusion.

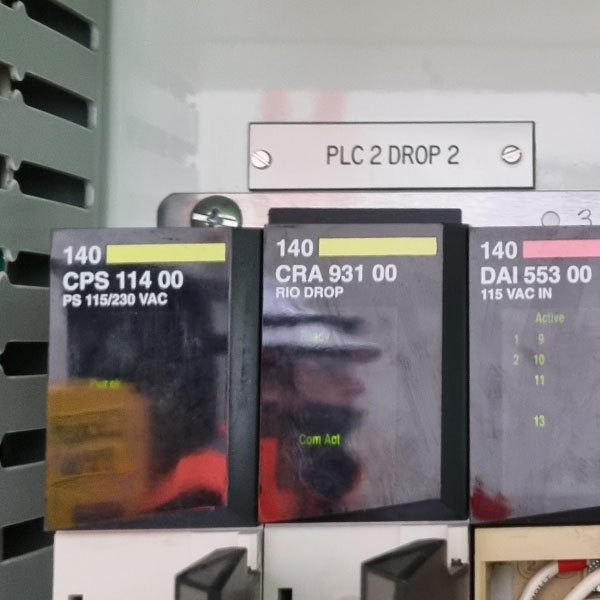

PLC Issue

Our client indicated that a PLC was starting conveyors and other equipment without an operator’s instruction.

The Redpoint Commissioning Team attended the site to investigate.

Our finding indicated the PLC control voltage was dirty, and we proposed installing a UPS to clean the supply.

Commissioning Assistance

Redpoint Engineering provides Contract Administration and Commissioning assistance on all design projects and projects designed by other providers. This service prioritises these projects to offer technical assistance before and during commissioning. Depending on the criticality of the issue, we are also available on-site or within 30 minutes of the site to collaborate with all parties to resolve problems.

Batch Weigher

Our client weighs their product before dispatching it. The valves that control the product entering and leaving the weigh hopper reached their end of life and require replacement. This project replaced these valves and extended the facility’s life. The project was explosive and was clasificed as a hazardous area. As the facility is classified as an explosive, our expertise in this area was required.

Redpoint Engineering was responsible for designing the interface between the new valves and the existing PLC, including preparing the design documentation for the hazardous area dossier.

Do you have any questions about our services?

Contact us today to discuss your electrical engineering challenges or request a quote.